CLIENT TOOLS

Welcome to the Client Tools page. Here you can find resources for prepping and uploading your files, and helpful print design tips with examples.

UPLOAD MY FILES

with FTP software such as Fetch or Transmit

I don't have FTP software...

PHOTOSHOP for NEWSPAPERS

prepping files for newsprint

SFNM COLOR GUIDELINES

for color replication on SFNM printing presses

Print Design Tips & Guides

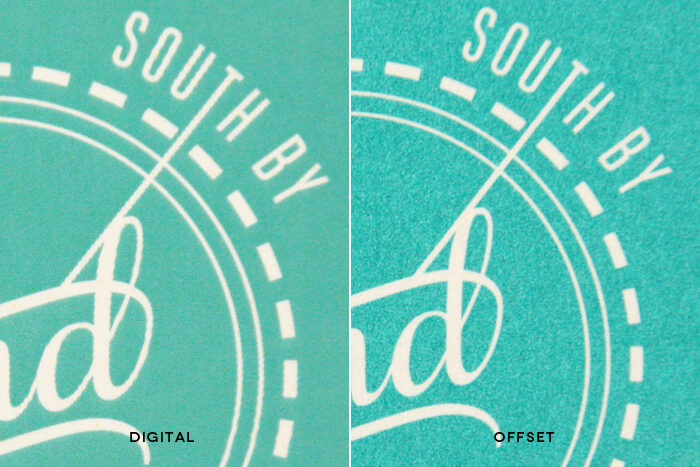

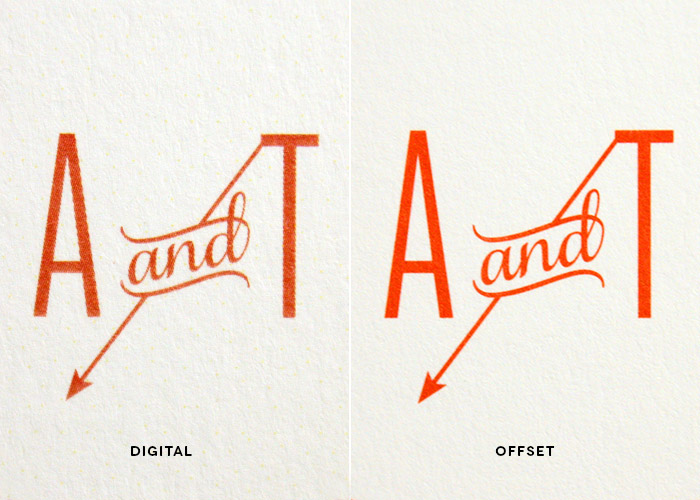

Digital vs Offset Printing

Bleed, Trim, Safe Area

Re: Color Management

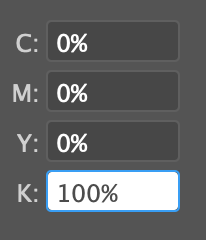

Black vs Black

100% Black and 4-Color Black on a single line of text.

Hold your finger over the image for a close up of the 4-Color Black.

Mixing inks to achieve a rich black will result in fuzziness, especially when applied to text. Perfectly sharp text and details can be created by using one process color value. 100% black (k) is as crisp as you can possibly get.

This is exactly how black should be configured in your design program:

0% Cyan

0% Magenta

0% Yellow

100% Black(K)

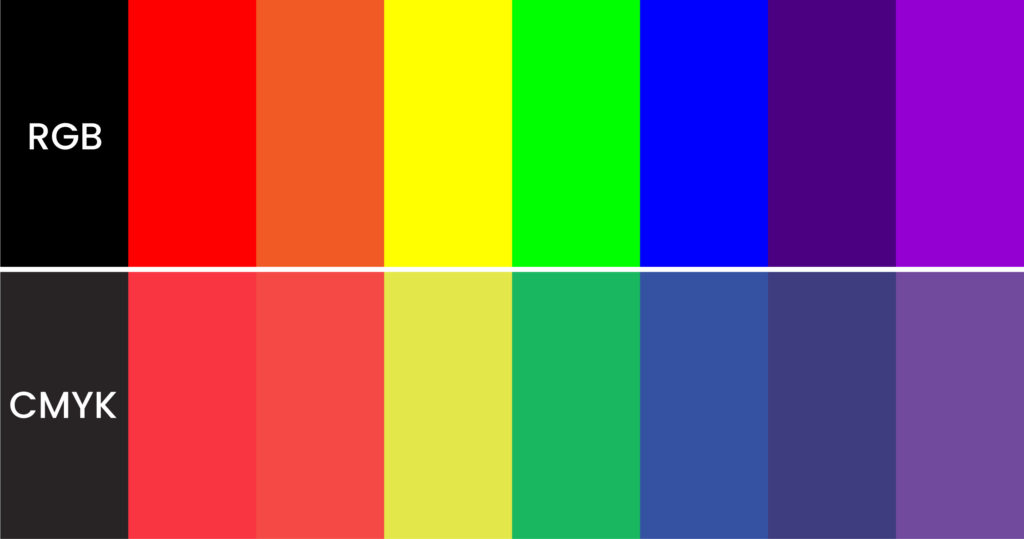

CMYK vs RGB

what you see on screen

how it will print

Re: Putting It On Paper

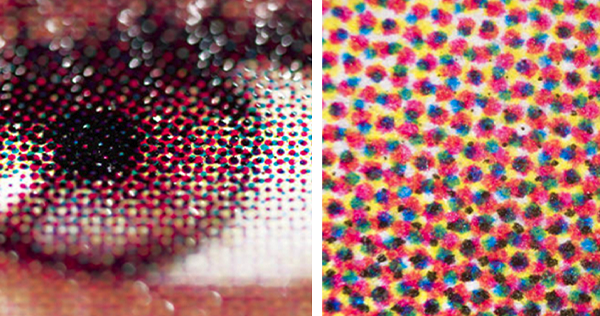

Ink Is Layered

CMYK inks are applied in layers of set patterns of tiny dots that appear to create a solid color. For this reason, it’s important to keep your total ink coverage under 260% (out of 400%).

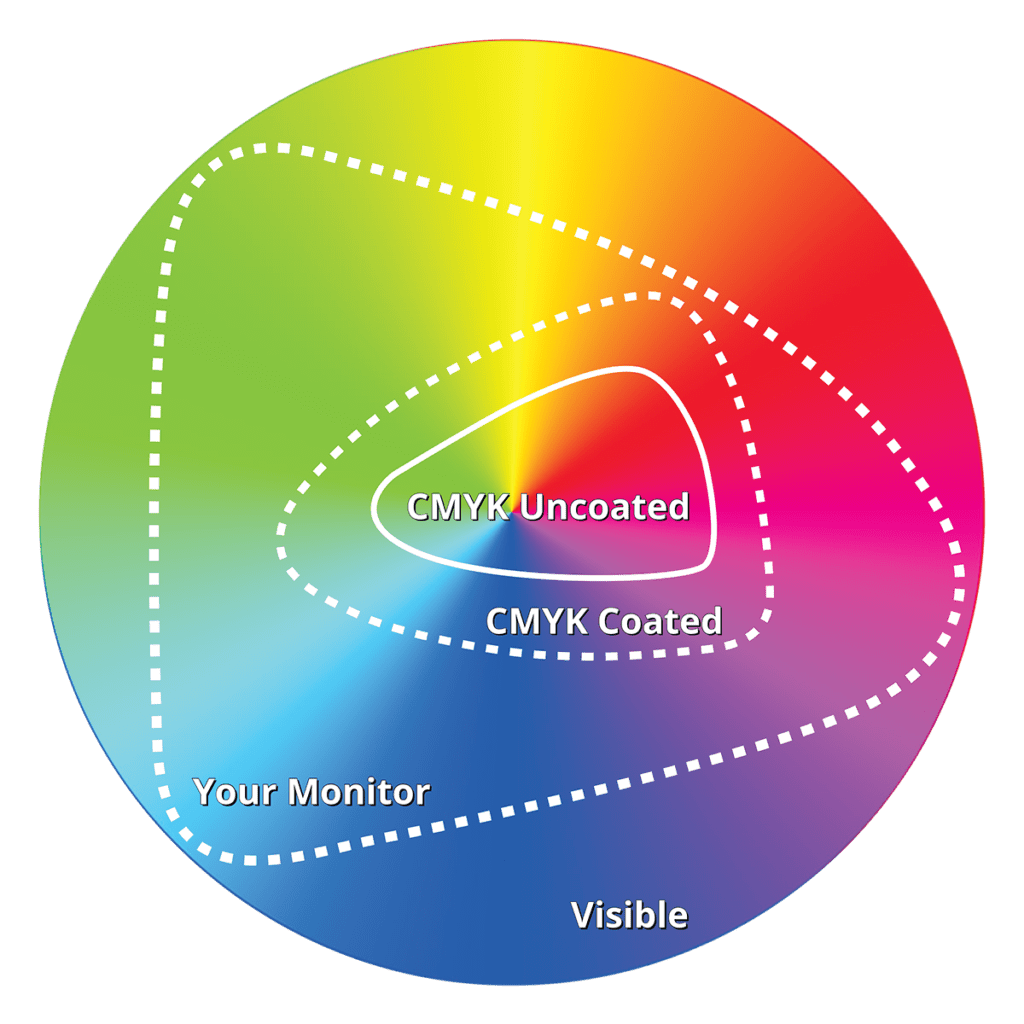

Newsprint Color Gamut

This chart represents the entire visible color spectrum, and the limits of reproducing them with ink on uncoated and coated paper.

Why does paper type affect color vibrancy?

MATTE PAPER & NEWSPRINT: Ink is absorbed into the fibers of water-soaked paper as it passes through the press. The paper air dries, but the ink never truly does, which is why your fingers might look a little dirty after holding a newspaper. The colors will slowly fade over time, but that’s what gives newsprint its distinctive character.

GLOSSY PAPER: Ink is cured on to the surface of the paper with ultraviolet light or another heat source as it passes through each process color on the press. The ink is permanently bonded, resulting in a durable product with vibrant colors.

Questions about print design or file management?

Send them to inquiry@sfnewmexican.com